Port and Harbor Transportation

"Since our founding in 1801 as a coastal operator at the Port of Shimizu, we have lived with the port for more than 220 years and accumulated trust, reliability and experience as a professional in harbor businesses.

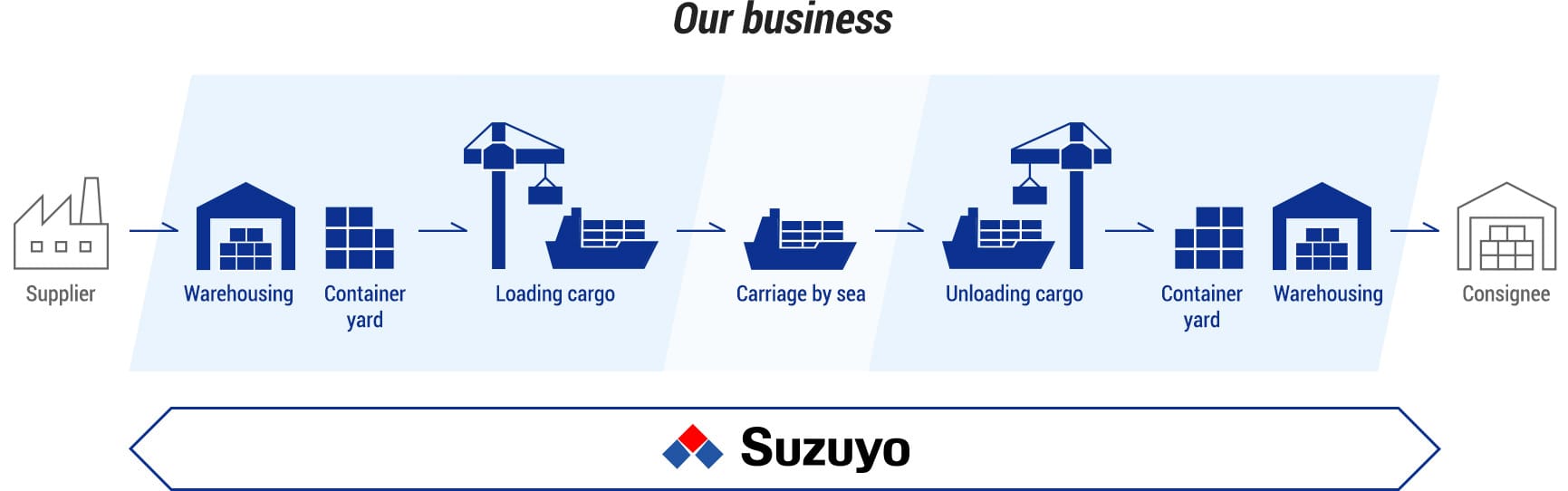

We provide a wide range of port and harbor transportation services from the stevedoring of conventional cargo such as bulk cargo and heavy cargo to container terminal operations.

Recently, we have newly started medium lot marine-transportation network "Hako-Kaisen" for hazardous materials and recyclable resources. We aim to provide port and harbor transportation services that can respond to the changes in the environment surrounding our customers."

Our Strength

Harbor stevedoring with reliability and experience

- Operating port and harbor transport businesses at the ports of Shimizu, Omaezaki, Mikawa, Ichihara, Hitachinaka.

- Through improvement activities, we construct a safe, productive and high quality operational formation.

- With over 300 staff of Suzuyo group, we can flexibly cope with peak/off-peak fluctuations.

Expert in container terminal operations

- The Shimizu container terminal operates without stop 24 hours a day, 364 days of the year.

- With consideration for eco-friendliness we have introduced hybrid/electric transfer cranes in Shimizu.

- We operate a private terminal at the port of Ichihara in Chiba which can handle hazardous materials.

Stevedoring for conventional vessel cargo and heavy materials transportation services for a wide range of cargo

- From bulk cargo such as cereals to hazardous material, recycable materials, bulky and heavy materials exceeding 100 tons per unit, a wide range variety of cargo can be handled.

- We handle nationwide integrated transportation of heavy products leveraging large cranes, trailers and domestic coastal vessels that we own.

- For lengthy and heavy duty cargo which cannot fit in containers, we provide carriage services using car carrier ships.

Service

Stevedoring for conventional vessels

- Over 300 professional stevedores with expertise skills and ample experience cope with wide ranging cargo including cereals, pulps, logs etc. Our service also covers supplemental affairs such as storage, clearance, transportation , etc. We are endlessly pursuing even safer and more productive services through the introduction of new handling methods and the development of new types of handling equipment , etc.

Container terminal operation

-

We are operating container terminals at the port of Shimizu and at several other ports. Through our accumulated know-how and systemization, Shimizu is now evaluated as one of the leading ports of Japan in both handling productivity and in/out container waiting time.

At the port of Ichihara in Chiba, we started private terminal operations in 2018 providing various services to solve various problems such as BCP and driver shortages , etc.

Medium lot marine-transportation network "Hako-Kaisen"

- Based on our concept of "Carrying uncarriables / When it cannot be carried carry it", we invented a new service leveraging containerization of hazardous goods and recyclable materials subject to handling regulations to cope with the aging/shortage of conventional ships.

RORO services at the port of Toyohashi

- Carriage services of lengthy/heavy cargo using car carrier ships. Mikawa port is the No.1 gateway port for landing imported vehicles and is connected to direct lanes with Europe/USA. Utilizing our own tow tractor and 200-ton crane we propose integrated transportation combining sea transportation using coastal vessels and land transportation leveraging our own special trailers.

Area

Port of Shimizu (Shizuoka-pref.)

- One of Japan's leading international ports handling a variety of goods including bulk conventional cargo like cereals, paper pulp and logs, container cargo and fossil fuels such as LNG and petroleum etc. Not only being capable of accepting various container ships from USA/Europe/Southeast Asian countries and international conventional carriers every month, it also serves for domestic traffic including coaster lanes (RORO, Mid-lot surface carriage) from/to anywhere in Japan. It also responds to customers' versatile needs with various logistic facilities such as huge handling equipment, packing services and fumigation facilities , etc.

Port of Omaezaki (Shizuoka-pref.)

-

Mainly focusing on the handling of complete 4-week vehicle, container ships and steel materials, we are coping with lengthy/broad and/or heavy-duty products leveraging our ample space within the port.

At our distribution center, we are also capable of domestic cargo and import/export containers. In 2023, we are expecting to start operating a biomath power plant whereby we hope for further development of the port as a base to support stable supplies of natural energy.

Port of Mikawa (Aichi-pref.)

-

At this port - Japan's largest (volume-wise) imported car port - we operate the handling of cars exported/imported via car carrier ships. Cargo we handle also includes lengthy/heavy products carried by car carriers destined throughout Japan.

Also, our large cargo handling machines, steel storage warehouses and heavy duty trailers (that we own) allows us to act as a transfer base.

Port of Ichihara (Chiba-pref.)

-

The private terminal we own here enables us to handle products which are difficult to handle otherwise at a public terminal.

Areas within the yard are designated AEO bonded areas where both domestic and import/export cargo including hazardous goods and recyclable materials can be handled.

Port of Hitachinaka (Ibaraki-pref.)

- We provide wide ranging services including a USA bound container cargo handling agency, import/export affairs for cargo in the ports of the Tohoku area, warehousing, packing and other transportation. Since this Hitachinaka port is expected to function as a substitute of the Keihin ports, seemingly getting busier and busier, we are proposing to our customers in the north-Kanto and south-Tohoku regions who have needs for export/import to use this port for the purpose of BCP and to evade congestion at the Keihin ports.

Related business

-

International transportation & Export/import

Supporting a variety of needs related to transportation and complicated import/export affairs with rapidity and accuracy.

-

Domestic transportation

Providing high quality transportation services through our network of 43 locations located in Japan.

-

Logistic information service

Services which enable constant management/confirmation of customers' logistics.